Ford Campus Building

Dearborn, Michigan

Developer: Ford Motor Company

Architect: Snøhetta

Architect of Record: IBI Group

Engineer of Record: Ghafari

Sustainability and Engineering Lead: Arup

Pro-Bel services provided: Design, Engineer, Manufacture, Inspection, Load Testing and Supply and Install

Snøhetta has unveiled a new Central Campus Building for Ford Motor Company, part of its Research & Engineering (R&E) Campus transformation in Dearborn, Michigan. As the result of a 3-year research and planning process, the project was created in collaboration with IBI Group as the Architect of Record, Ghafari as the Engineer of Record, and Arup leading sustainability and engineering.

Supporting Ford’s aspiration to create an environment that allows it to lead the automotive industry into the future of mobility technologies, as well as its new work-from-home model, the Snøhetta project puts in place a Central Campus building.

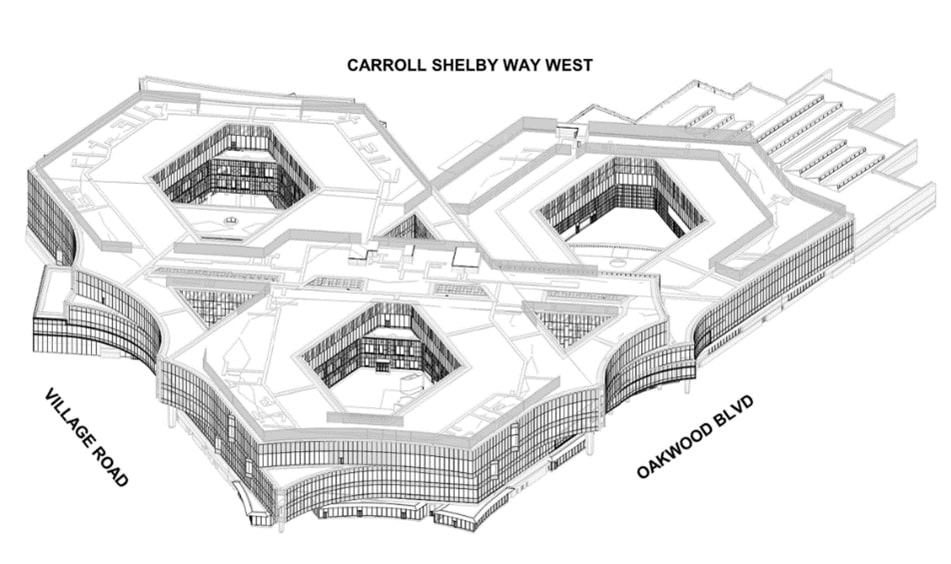

Part of the master plan for the Research & Engineering (R&E) Campus in Dearborn, Michigan, also designed by Snøhetta, the structure is imagined as a “resource that gives employees a place to come together and facilitate the easy flow and circulation of ideas”.

In fact, the interconnected and resilient workplace of the future is centred on catalyzing opportunities for health, collaboration, co-location, and product innovation.

Bringing together a technologically advanced workplace with productive landscapes, the new Central Campus Building will be a space for approximately 6,400 employees from Ford’s many disciplines, including design and engineering.

It will include amenities, offices, design studios, fabrication shops, laboratories, and courtyards as a network to create proximity between people and products, allowing cross-disciplinary teams to work together around a product line within physical and visual proximity.

Moreover, it generates functional spaces, such as design studios, and serves as a community asset, located near Oakwood Boulevard and activated with public amenities to engage the community.

Creating connections across floors, the new workplace will allow for expansion and contraction. Transitioning from a closed to an open campus, the Central Campus Building will create a new public face for Ford opposite notable landmarks such as the Henry Ford Museum and Greenfield Village.

From plazas and courtyards to paths and gardens, the campus landscapes are each productive. Finally, capturing and managing stormwater on-site links planting areas with stormwater channels and site features to create diversity and seasonality across the full campus.

Pro-Bel's Fall Protection Solution

Due to the scale of this project, it’s safe to say that only two companies in North America could successfully complete it —Pro-Bel being the first.

During the sales process, we not only made the above statement clear;

We explained to the project team (comprising the owner, architect, engineers, general contractor, etc.) that we understood the building and the intent of the Davit System (designed and specified by a Consulting Engineer), and that it required a couple of changes.

However, fall protection was completely different. Through our initial analysis, we noticed a need that we could fill and provide value to the project rather than simply pricing what was on the plans. We pointed out that the fall protection, a separate system on the architectural plans from the façade access, had numerous design conflicts and was not congruent with the Davit Design.

The fall protection was not designed properly. We proposed that Pro-Bel design the fall protection system and bring it together with the davit system for façade access. With that in mind, Pro-Bel initiated the project as a design and engineering contract.

The project drawings were divided into 35 separate sectors, creating a complex puzzle of roof areas. Each area needed to be connected to the next, piecing it together to ensure continuity of fall protection coverage with the Horizontal Lifeline System. An added complexity that should never be overlooked. The concept design of the fall protection system took almost 3 weeks.

Following the design of the fall protection process, we provided the concept with our proposal to supply the equipment, which resulted in a very large change order.

This is the largest value project in Pro-Bel’s History (excluding building maintenance units). We worked with a new manufacturer to save approximately $95,000.00 on the bulk manufacturing of the davit bases.

To allow ample time to supply the davit bases, we worked with the general contractor and steel erector to supply the davit pedestals that would provide a mounting plate above the roof. Pro-Bel supplied the davit pedestals and installed them by the G.C. self-performing trades, substantially reducing Pro-Bel's risk and exposure to delays.

The Davit system design required a custom load of 1300 lbs for the suspension of 600lb glass panels.

The project has an Interior Monorail at the Skylights, which is accessible through hatches located in the parapet wall of the skylights. The monorail in the Atria is accessible from a small aerial lift on the floor levels below. Monorail installation requires specific training; therefore, Pro-Bel is self-performing the installation.

Additional on-site labor includes visual inspection, static load testing of the permanently installed equipment, and installing the 10,146ft of cable to complete the horizontal lifeline system. A special operations team is managed outside of standard operations to complete this project successfully.