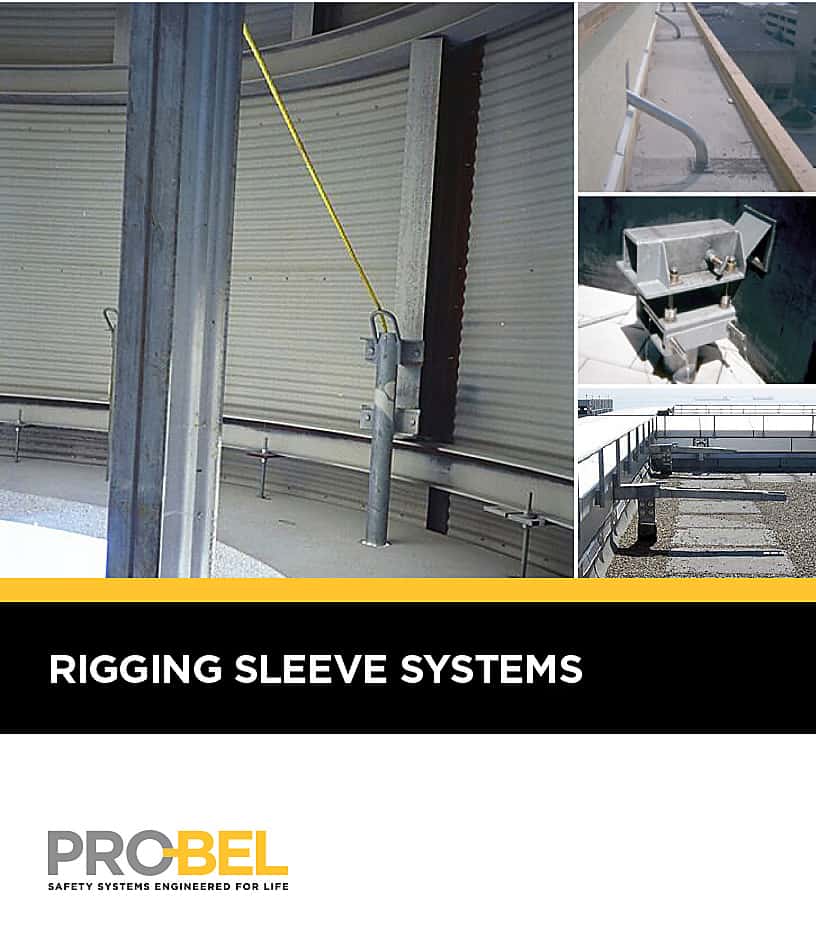

Rigging Sleeves for Window Washing

A rigging sleeve is a type of full custom window-washing equipment installed almost anywhere on the building that workers can reach to tie their lines. Window washing rigging sleeves are made of corrosion resistant materials such as stainless steel and hot-dip galvanized steel. All models OSHA and ASME/AINSI/IWCA safety requirements.

Rigging sleeves have solved many window-cleaning access problems by providing pathways through roofs, floors, walls, or other vertical elements for suspension lines where access would otherwise be difficult, unsafe, or impossible.

Rigging sleeves are primarily a redirection system that allows maintenance platform suspension lines and/or lifelines to be rerouted or fished through pipe sleeves. They can be any length or shape and adapted to suit virtually any building condition. Pro-Bel provides custom rigging sleeve solutions for each building project.

When is this form of façade access/window washing equipment implemented?

Window washing rigging sleeves are installed only when all other means of conventional equipment cannot comply with a building's architectural or structural characteristics.

They’re placed for safe, convenient access to primary suspension lines or lifelines through the roof, floor, wall, or other building elements. They can also access sloped roofs, overhangs, skylights, or otherwise inaccessible areas. They are suitable for use with a platform, single work cage, or bosun's chair with ascending capability.

They're set up when all other means of conventional window washing equipment cannot comply with a building's permanent architectural characteristics.

For safe, convenient access to primary suspension lines or lifelines through the roof, floor, wall, or other building elements. otherwise, accessing sloped roofs, overhangs, skylights, or otherwise inaccessible areas. Also recommended when all other conventional means of performing window cleaning/suspended maintenance cannot be used. Suitable for use with a platform, single work cage, or bosun's chair with ascending capability.

Types of rigging sleeves:

Wall Sleeve:

A sleeve was built into the wall’s structure. They are suited to a broad range of building structures, including concrete, structural steel, precast, etc. Securement methods include but are not limited to, cast-in-place, bolt-through, bolt-around, and welded.

When not in service, rigging sleeves retract to the interior of the building. They can be considered a form of “hidden window washing equipment.”

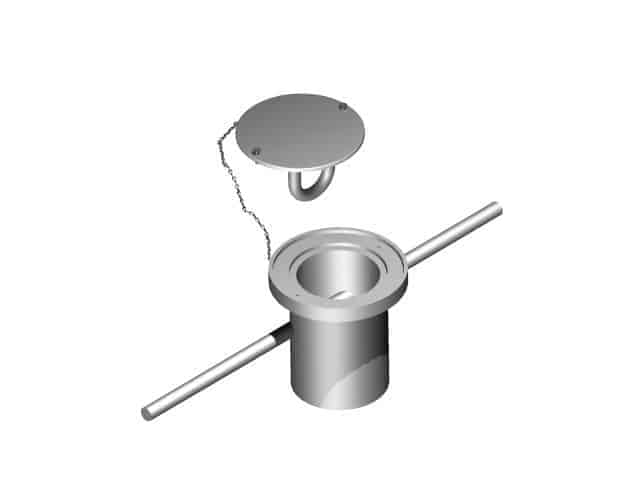

Flush-mounted rigging sleeves:

These are integrated into the balcony and designed with a cap concealing the rigging sleeve hole. They can be installed in a wide range of structures and are customized to meet building requirements.

Curved Rigging Sleeve:

These types of sleeves are used when the worker's suspension and lifelines must be run both horizontally through a wall and vertically through a soffit (such as in a mansard roof condition).

Vertical Rigging Sleeve:

When rigging over or around a façade is impossible, vertical rigging sleeves pass through the overhang or protruding building element (i.e., balconies or eyebrows) and are often a more economical solution to monorails.

Types of vertical sleeves Pro-Bel offers:

Horizontal rigging sleeve:

Horizontal rigging sleeves are used when building elements need to be passed through a wall horizontally to suspend the lines vertically for a ground-rigged suspended platform.

Types of horizontal rigging sleeves Pro-Bel offers: