The Benefits of a Monorail System

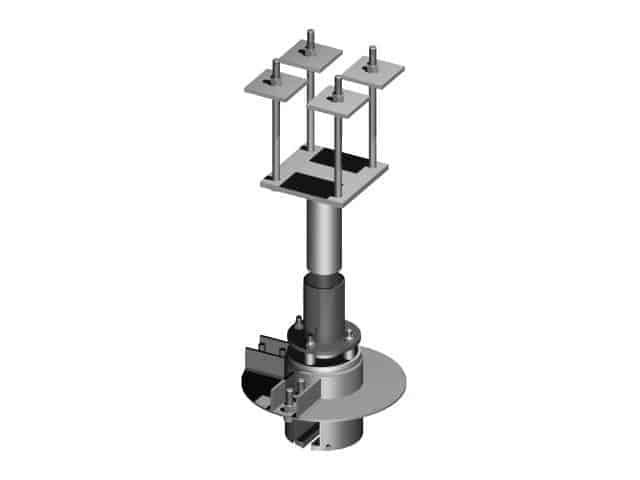

Suspended access monorail systems offer an efficient solution for facade cleaning, allowing access to challenging or otherwise inaccessible exterior and interior glass areas. These systems allow workers free access to indoor and external regions otherwise rendered inaccessible. A Pro-Bel monorail system acts as a continuous anchor system, which is ideal when rooftop equipment installation is impractical or even impossible.

Monorail Components

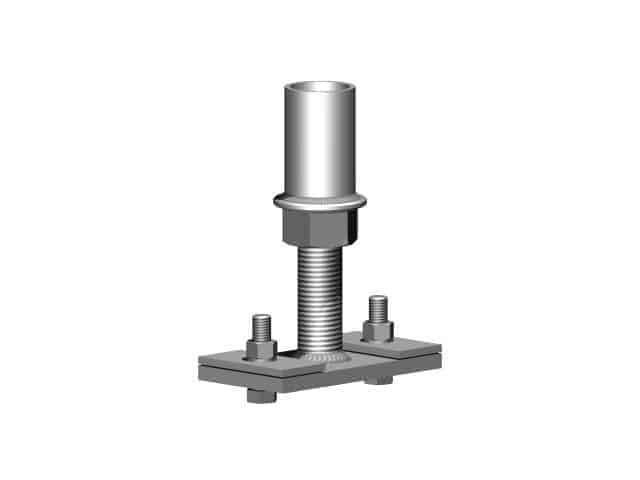

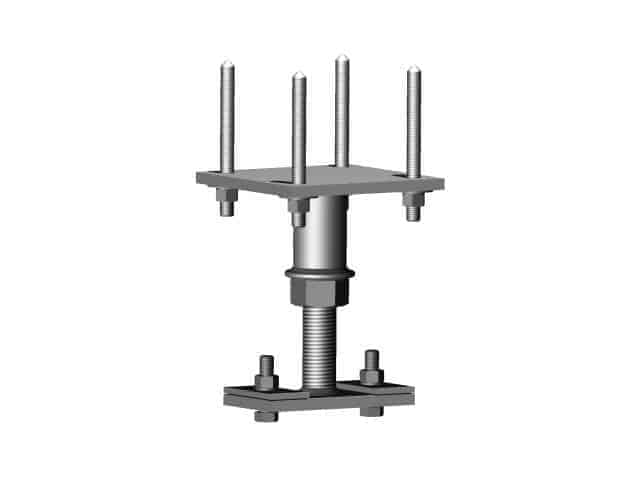

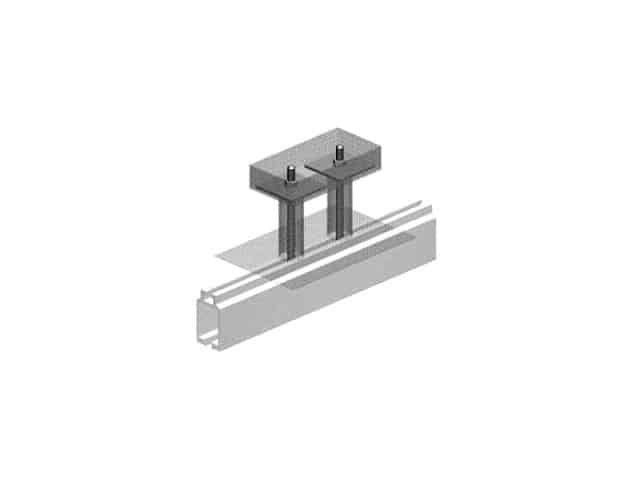

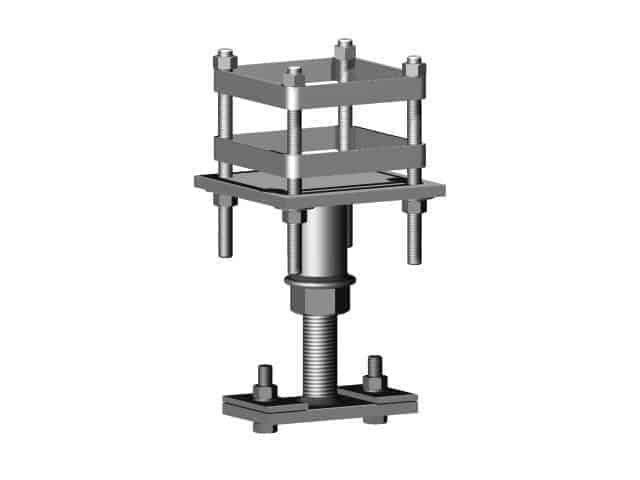

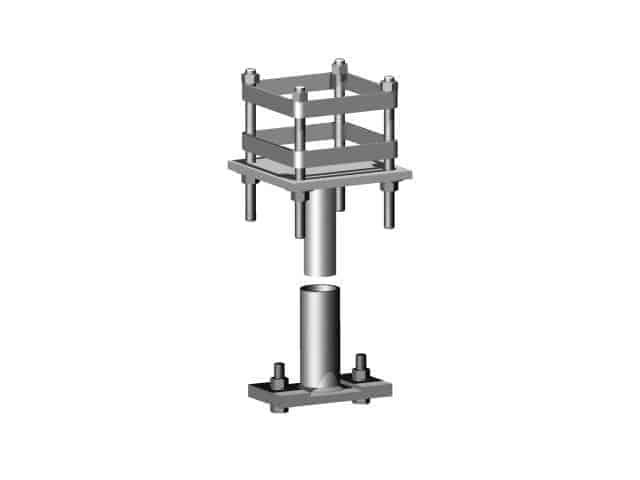

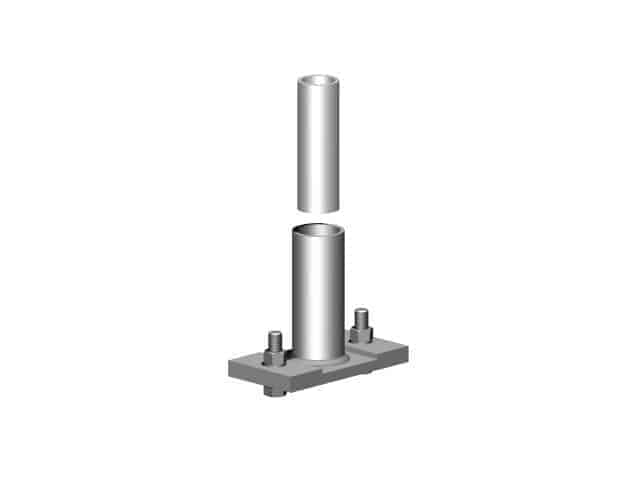

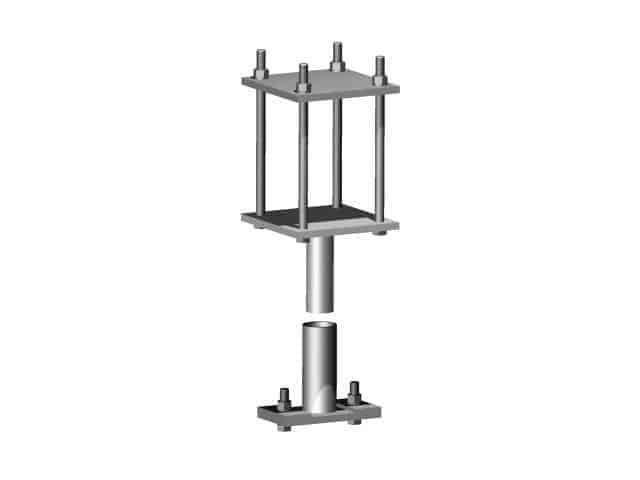

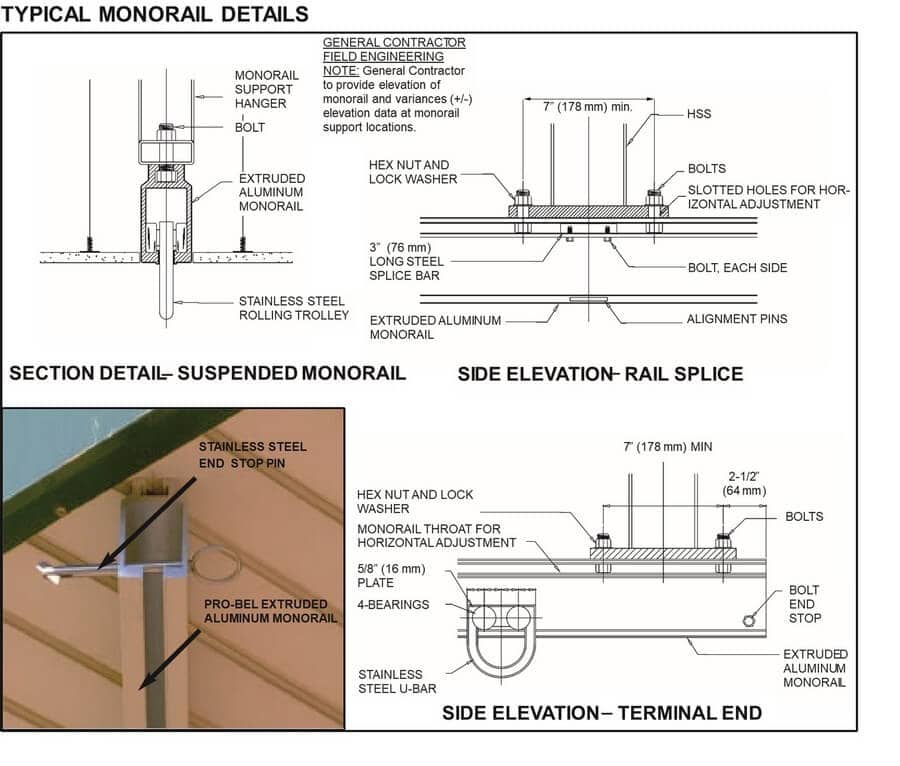

The key monorail system components are an Aluminum Rail Section, the Supports, and the Platform Trolleys. The list below provides more information about these components.

- Aluminum Rail Section: The central element of the system, supporting a manual or electrically powered traversing trolley.

- Supports: They are installed at intervals of 10’-0” to 12’-0” (3050 mm to 3658 mm) along the building, with additional supports at corners and for curved tracks.

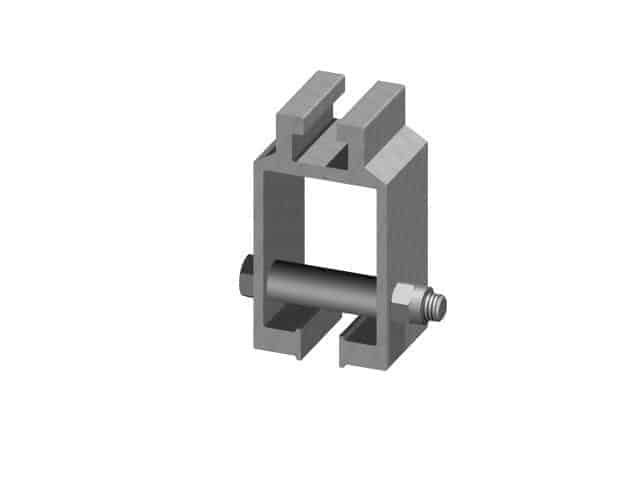

- Platform Trolleys: Four trolleys are required for a two-person platform: two for the primary suspension (platform) and two for the workers' lifelines.

Trolley Types

There are four different types of trolley – Manual Trolley, Manual Chain Trolley, Motorized Trolley, Battery Operated Trolley, and Climbing Trolley. Each different type of trolley is suited for different purposes:

- Manual Trolley: Operated manually for straightforward use.

- Manual Chain Drive Trolley: Utilizes a chain mechanism for movement.

- Motorized Trolley: Powered by electricity for smooth operation.

- Battery Operated Trolley: Runs on batteries for greater flexibility.

- Climbing Trolley: Designed for vertical movement on the monorail.

Rails: Available in straight or curved configurations (90-degree, 45-degree, or circular), with a minimum radius of 3-0” (915 mm). Rails can be exposed or concealed within soffits or ceilings.

Accessing a Monorail System

To access a monorail system, workers first approach the monorail via a localized window, hatch, rigging sleeve, or ladder. Once they have accessed the monorail, the worker suspends their safety line from the monorail and returns to either the first floor or a lower level (if working externally) to ground rig their platform. One of design professionals' most commonly overlooked aspects is the inclusion of localized access to the monorail and fall protection for workers on their way to the access point.

Applications

- Ideal For:

- Building overhangs

- Sloped glazing and skylights

- Atrium glass

- Domes

- Compatible Equipment:

- Building overhangs

- Sloped glazing and skylights

- Atrium glass

- Domes

Alternative Types of Monorail Systems

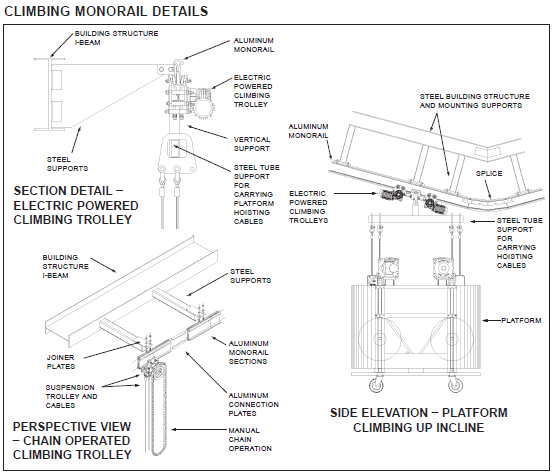

If a typical monorail system does not meet a building’s needs, it can be substituted for a gantry system, climbing monorail system, or a horizontal trolley rail system.

A Climbing Monorail Trolley System is the ideal solution for sloped interior areas. It can additionally be used for external facade work in cases of a building that has a curved or sloped facade. They’re designed to be able to traverse smoothly along either a horizontal or vertical monorail, even ones with twists and curves, making them an excellent choice for washing and maintenance of indoor locations such as large lobbies.

Pro-Bel’s specialized climbing trolleys employ two power packs that utilize friction between the wheels combined with a specially designed aluminum monorail. When used outdoors, these systems can operate safely even on frosted over or wet railings, enabling safe proper usage year-round no matter the season.

A horizontal trolley rail system is not used for window cleaning; it’s a rooftop fall protection system. It’s a horizontal lifeline system that uses rails rather than tie-off anchor points. This fall protection solution is used as a substitute for other similar systems.

Monorail System Details

Pro-Bel Monorails

Share this Post