Fall Protection System Design is a highly specialized area. At Pro-Bel, we have a design process to ensure your system meets state/provincial and national regulations for your buildings’ unique rooftop fall protection system requirements. Our Design Service is also FREE for any eligible projects (a majority of projects qualify, please contact us to learn more). Some highly complicated projects may require a fee.

Understanding Fall Protection and Window Washing Systems

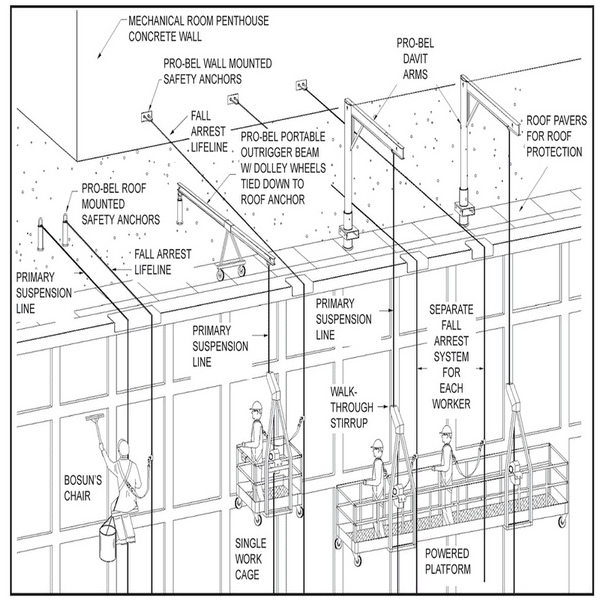

A fall protection system is a rooftop anchor point layout that workers attach themselves to in order to be restrained from potentially falling over the roof edge. A window washing system refers to the equipment aligned with all windows of the building that window washers use to suspend themselves down the side of the building. Window washing systems include a fall protection system for the worker’s lifelines.

AT PRO-BEL, THERE’S NO PROJECT TOO SMALL OR TOO TALL; WE DO IT ALL.

Projects that require fall protection and/or suspended access can come in all shapes and sizes. We’ve worked on buildings ranging from 2 to 99 levels. For each building maintenance solution, there are essential design considerations that must occur at the preliminary planning stage.

Initial Requirements

To begin designing your Fall Protection/Window Washing System, we require the following most up-to-date plans:

- A complete set of Architectural Plans (roof plans, floor plans, elevations, details, wall sections, and any other relevant documents to create an optimal design)

- Structural Drawings

- Mechanical Roof Drawings (if available)

- Landscaping drawings (if they pertain to the roof)

Sometimes, additional drawings may also be required if there are any unique building conditions present. A design can be made from just the architectural drawings, but it will need to be reworked once the structural drawings are available.

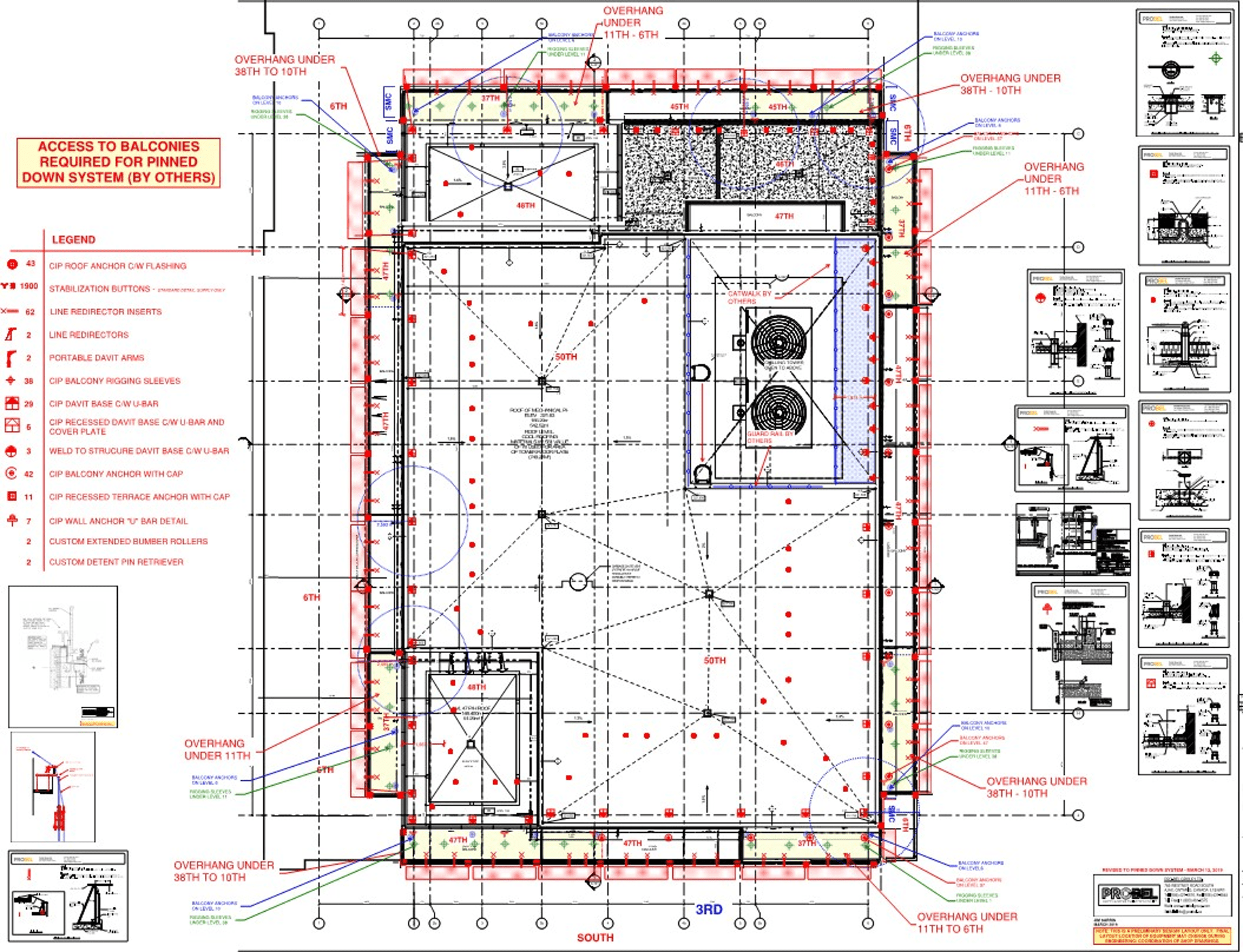

See an image below of what a typical design by Pro-Bel might look like.

Design Process

Once we have the drawings, we begin our design process. Each system is custom-made to fit the building's conditions. Generally, our experts start with the simplest and most cost-effective solution: our permanent roof/tie-back anchor system.

Watch How to Design A Rooftop Fall Protection System

If anchors are insufficient to create safe and complete access to the façade, we move on to designing with davits, outriggers, and other equipment:

- Davits: Window washing davit arms can hold a significant amount of weight and focus their support on a single anchor socket, allowing them to support even powered platforms.

- Outrigger Beams: More useful for single-person tie-offs rather than platforms, outrigger beams can be portable but require more space on a rooftop compared to davit systems.

Top 6 Considerations for Designing a Fall Protection System

Pro-Bel engineers and manufactures a wide variety of equipment that can accommodate virtually any building condition. For example, rigging sleeves allow access through a roof, when going over the parapet is not an option (which can be the case for several reasons). The building foundation’s material is something that our skilled engineers will consider as well – tie-back anchors for metal roofs will have to be welded onto the I-beam directly instead of cast into a floor or wall, as could be done with other roof materials.

1. Codes and Regulations

Once we have your drawings, the next step is ensuring compliance with the relevant codes and regulations, which vary by location.

USA (excluding CA and NY)

- OSHA 1910 Subpart D – Walking and Working Surfaces

- OSHA 1910.66 Subpart F

- ANSI/IWCA 1-14.1 – The Window Cleaning Safety Standard

- ASME A120.1 – Safety Requirements for Powered Platforms and Travelling Ladders

Canada

- CSA Z91: Health and Safety Code for Suspended Equipment Operations

- CSA Z271: Safety Code for Suspended Platforms

- Each province has its own regulations; visit Pro-Bel Canada for a detailed list.

Harmonizing between applicable standards and regulations is complex. Pro-Bel has extensive knowledge of these codes and can help determine what applies to your project, offering liability protection through our comprehensive design.

2. Building Height

One of the first factors we assess is building height, as it often determines the types of approaches we can and cannot use. For example, regulations prohibit using a bosun’s chair/rope descent system for drops exceeding 300ft (90m), requiring suspended platforms/stages instead. For buildings taller than 490ft (150m), a BMU/roofcar solution is typically necessary.

Façade Stabilization

For buildings over 130ft in the USA or 45m/150ft in Canada, intermittent stabilization anchors/buttons are often used. An alternative is the mullion track system, though building geometry may limit its use.

3. Fall Restraint vs. Fall Arrest

Fall Restraint

This approach keeps workers outside the fall hazard area (within 2m or 6ft6in of a roof’s edge). Equipment is placed to restrain workers, typically using stand-alone anchors or a Horizontal Lifeline system.

Fall Arrest

This approach stops a fall if it occurs. The fall must be arrested within 1.5m in Canada and 6ft in the US. There must be at least 20 ft/6 m of vertical distance to arrest the fall properly. If this is not possible, travel restraints or guardrails must be used.

We prefer designing fall restraints to avoid fall risks whenever possible.

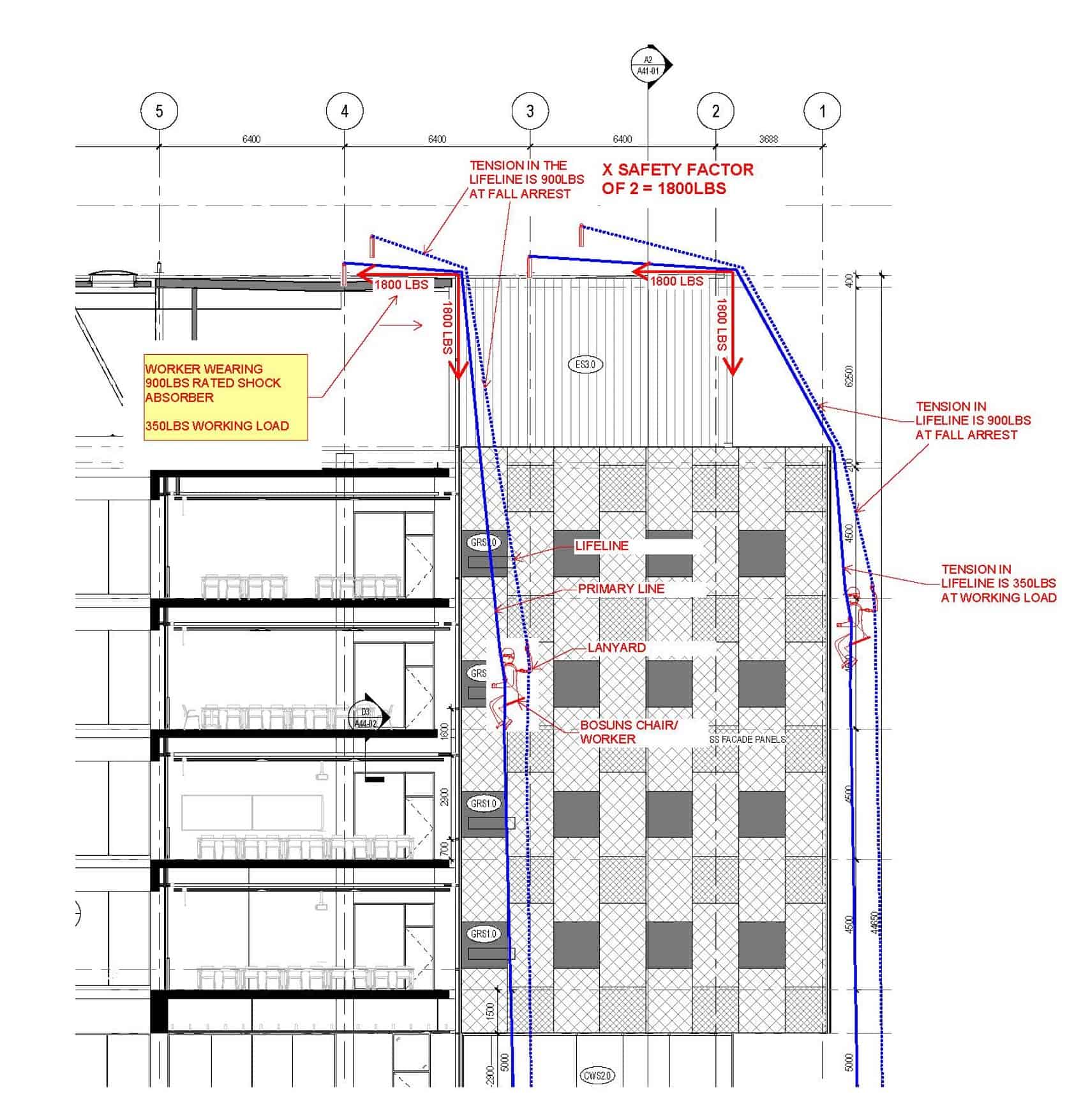

4. Direct Loading

Parapets are common elements we coordinate with. They should be designed to withstand the following loads:

- Working load: 310lbs

- Fall Arrest Load: 900lbs

- Factored Fall Arrest Load: 1800lbs

The loading is based on 310lbs worker and tools/working load, if the worker falls it creates an instantaneous peak force of 900lbs on the parapet which is the fall arrest load. The factor on this load is typically 2:1 therefore, parapets generally should be designed for 1800lbs factored load horizontally and vertically.

Another important element to consider is that if a fall is to happen, how will the parapet edge react and most importantly that no piece of the parapet/façade will fall off and harm the worker or general public below.

If direct loading isn’t possible, we use solutions that clear the parapet without placing any load on it.

5. Equipment Location

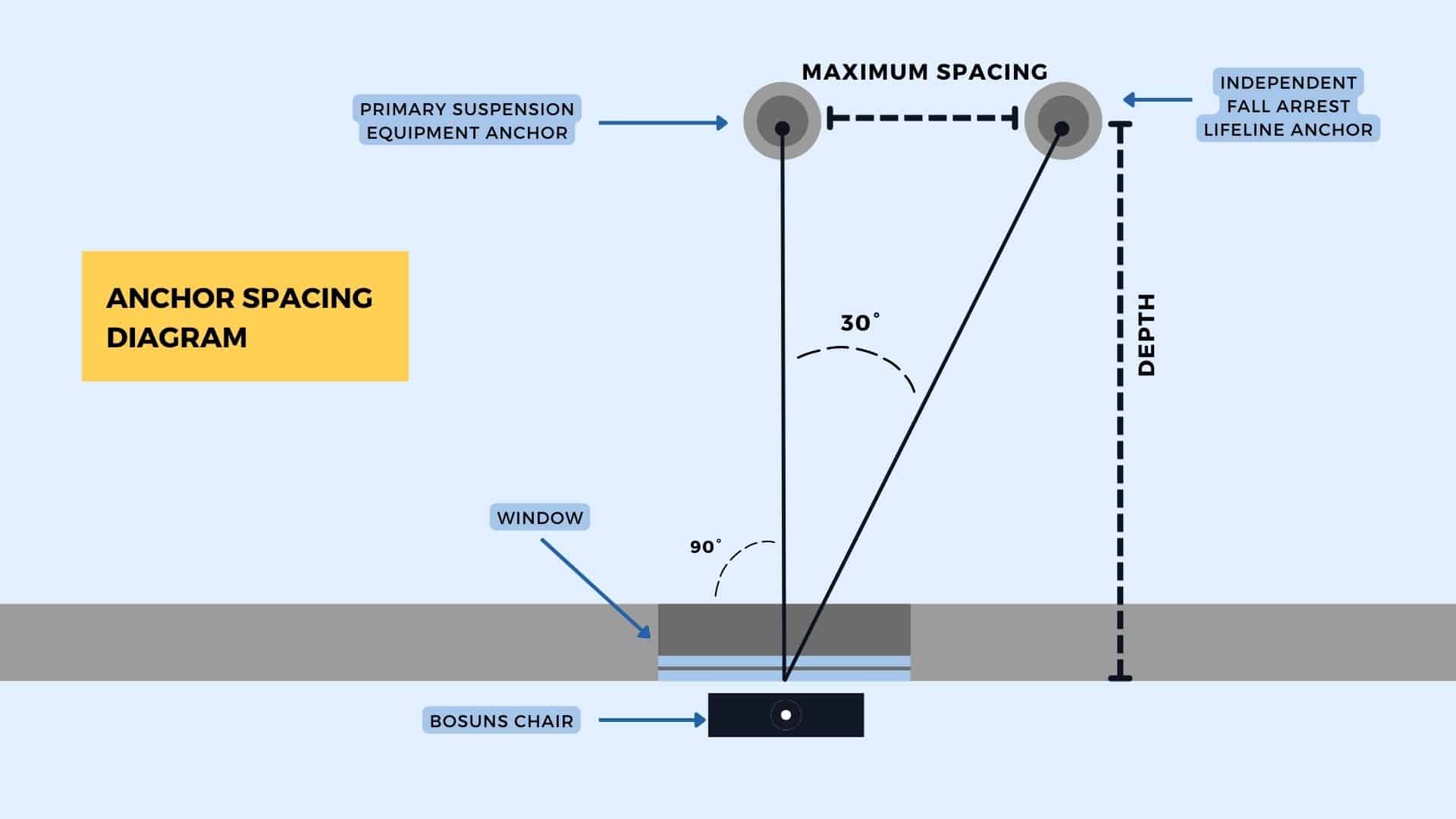

Equipment location ensures safe use of building maintenance and window cleaning systems. Designers adhere to the 30-degree rule to prevent excessive force on the body during a fall.

Anchor Placement

When anchors are located closer than 3m (10ft) to the parapet, they should not exceed 1.5m (6ft) apart. The farther back from the parapet, the more they can be spaced out.

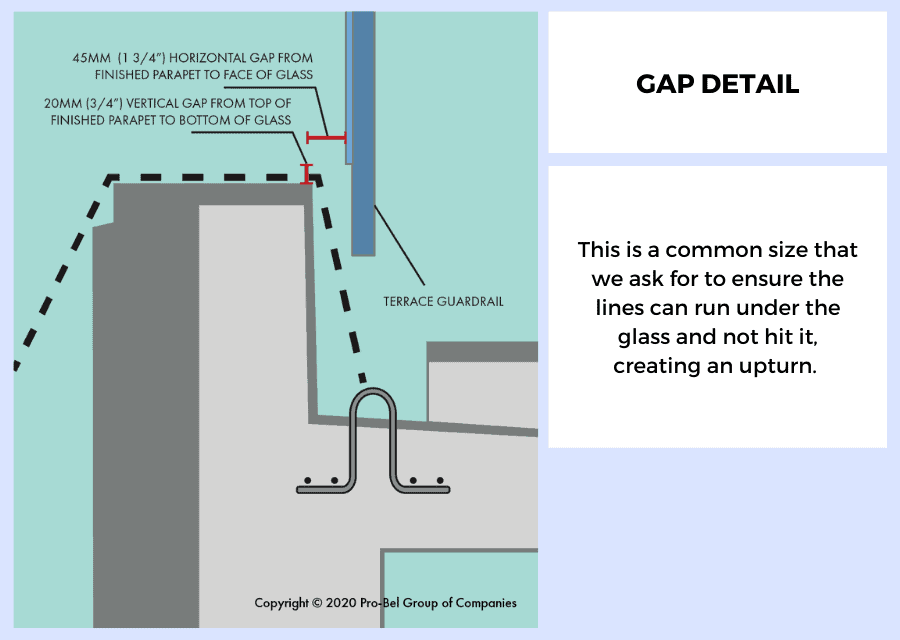

6. Gap Detail

Public terraces often include glass guards. To keep cleaning solutions cost-effective, we recommend a gap between the parapet and the guard, allowing lines to run under the glass without creating an upturn.

We've also made our gap details available for download; check out our blog on gap details that every architect should know.

Safe, Functional, and Economical Approach

We design our systems for safety, functionality, and economy, aiming to reduce initial and future maintenance costs. Our goal is to assist with keeping window washing and exterior maintenance costs as low as possible.

Addressing Misconceptions

There are two common misconceptions related to the design of window washing equipment.

- Standardized System: Each building is different, and thus, every building requires its own individual and unique approach to design.

- Code Compliance Only: Meeting Codes and Standards is crucial, but a design must also allow contractors to perform their duties effectively. A properly designed fall protection system serves both building owners and workers.

Contact us to see if your project is eligible for a free design or if you'd like more information.

Share this Post