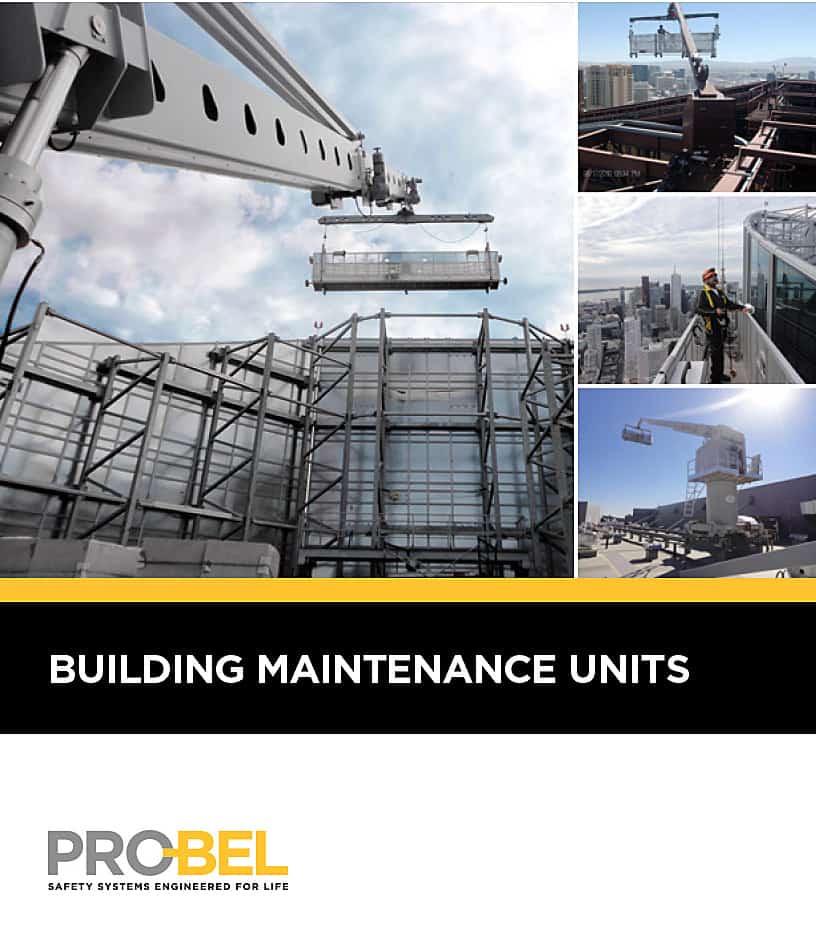

Building Maintenance Units (BMUs)

Building maintenance units (BMUs), also known as powered roof cars, are engineered to accommodate long-span booms making it possible to extend the platform beyond terraces or roofs at lower levels. This feature can reduce or eliminate the need for additional roof cars, davits, or other primary equipment at lower levels.

Another consideration in "super-skyscraper" applications is the length of the control cable required to operate the hoisting mechanism. To eliminate the need for a control cable between the platform and the roof car, Pro-Bel employs a remote-controlled hoisting system or control cable interwoven with any one of the four platform suspension cables to raise and lower the platform.

When is this form of façade maintenance/ window washing equipment implemented?

Powered roof cars, also known as BMUS, are mandatory for buildings exceeding 492ft (150m) in height. Many traditional forms of permanent support equipment such as davits, outrigger beams, monorails, etc. are impractical on skyscrapers and thus require a roof car for façade maintenance.

Powered roof cars can be installed on buildings under the height requirement, but it's generally not recommended given the high cost and maintenance needed. However, if other forms of permanent support equipment cannot suit the building, a roof car will be considered.

CSA Z91-17 - HEALTH AND SAFETY CODE FOR SUSPENDED EQUIPMENT OPERATIONS

"Davit systems shall not be used if the suspension height exceeds 150 m (492 ft). Note: Roof-level hoists and roof cars are recommended on buildings over this height. Use of outrigger systems for suspension heights over 150 m (492 ft) should be restricted to during construction or renovation when the system has been engineered." - 6.5.6.10.2 Davits - Restricted Height.

Types of Building Maintenance Units (BMUs)

There are many design considerations when determining the specific type of BMU to implement. You can find more information here. These are the two standard models:

BMU with traction hoists and wire winders on the platform:

This design is suited to buildings under 490'-0" (150 m) in height, however, the platform is typically small e.g. maximum 10'-0" (3 m), to accommodate the added weight of the suspension lines and power cord. The benefits of this type of roof car include being able to transfer the platform to other roofs for use with conventional supports, e.g. davits, outriggers, monorails, etc., and platform occupants can lower the platform to the ground using a descent control feature in the event of a power failure.

BMU with drum hoists at roof level on the roof car:

This design is suited to buildings over 490'-0" (150 m) in height requiring a platform longer than 10'-0" (3 m). The benefits of this type of roof car include eliminating the added weight of the suspension cables which are now coiled at roof level using drum-type hoists. Also, to eliminate the added weight of the power cord on the platform, a control cable can be interwoven in any one of the suspension cables or a radio-type remote control can be used to raise and lower the platform. A limitation of this type of roof car is that with the main controls at roof level, in the event of a power failure a communication and training system is necessary to permit a worker on the roof to activate the descent control apparatus allowing the platform to safely descend to the ground.