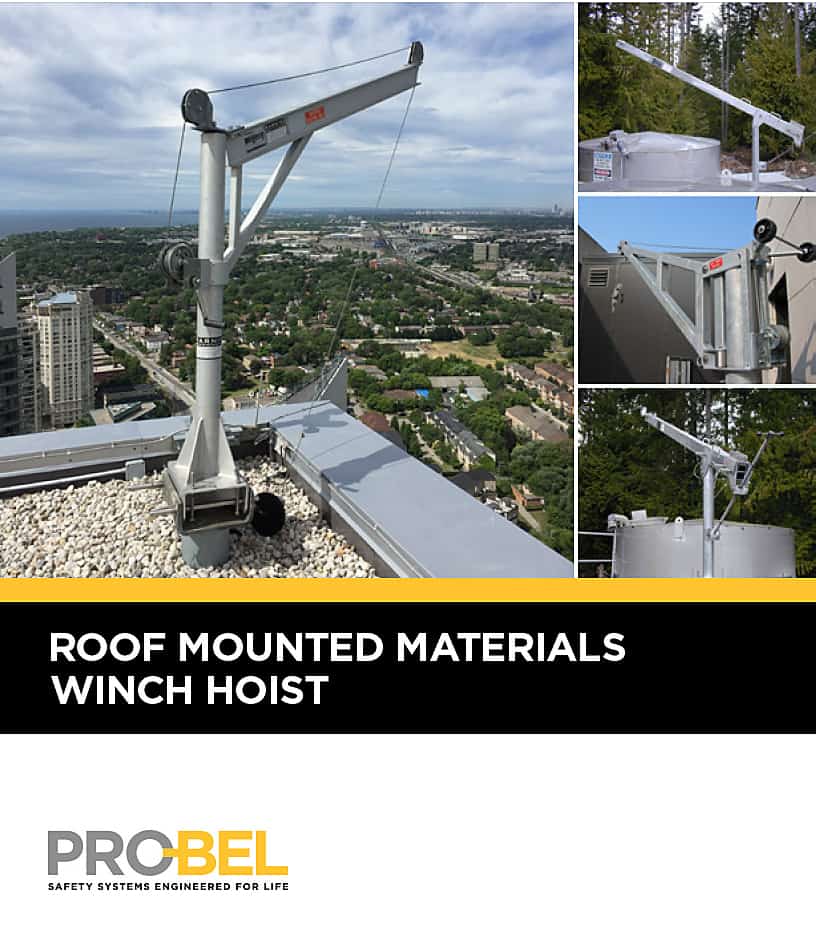

Roof-Mounted Material Hoists

Enhance Your Building's Efficiency with Reliable Material Hoisting Systems

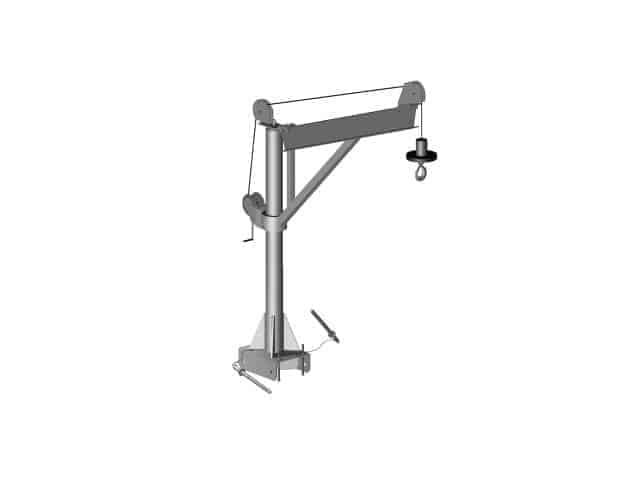

A roof-mounted material hoist is a type of davit that lifts materials and equipment to the upper floors of buildings. The hoisting arm can lift 350-1000 lbs at a time and is not meant to lift people. Material hoists are typically installed in industrial buildings or hospitals, given these buildings are more likely to need to lift equipment to upper floors without disturbing the work being done in the building.

Understanding the Winch Hoist Davit Arm

When looking at a winch hoist solution, it is ideal to understand the pressure or force you are trying to exert fully. Some people use these terms interchangeably, but there is a difference between the two, and it's important to understand that difference before you decide which options are best suited to your line of work and the task you want to complete.

When you know the difference, you can be sure that you are getting the right tool for the job. If you are not sure, our team will stand by to explain the differences. We can assist you and guide you towards the ideal solutions from our range.

Lift VS Pull

- Winches are designed to pull loads horizontally across a relatively level surface.

- Hoists are engineered to lift loads vertically and suspend them in mid-air.

These specific roles allow you to maneuver objects around a space easily. In many industries, from construction to window washing and event rescue procedures, these handy devices ensure you can get your load to where you need it to be on site. While there are combination elements to be purchased, the main functions of these systems must be understood so you can ensure your purchase will get the job done right.

Are They Interchangeable?

Generally, winches and hoists are not interchangeable, as each is designed for a specific task. Using a standard winch to lift loads vertically is unsafe because winches are typically designed for horizontal pulling. The key difference lies in their braking systems:

These tools are usually designed to complete a pulling task along a horizontal plane, which means there is a large risk of a winching load dropping as it puts direct vertical weight on the drive means for flat pulling.

- Winches use dynamic brakes to support rolling loads but are not equipped to handle the sudden vertical lifting of deadweight. If used improperly, this could cause the load to fall and potentially damage the system. The gears of a dynamic braking system automatically lock when pulling a load, but lifting a weight vertically can overwhelm the strength of this system, causing the load to fall downward and potentially causing massive harm to the operating system.

- Hoists use mechanical brakes designed to lock and support deadweight in vertical lifting. These systems are better suited for vertical lifting tasks and often come with load limiters to prevent overloading from attempting to lift a weight that exceeds the actual working load limit.

A Combination

However, some overlap exists as certain winching products are designed to double up as a hoisting system. These specially designed solutions have been tested as a dual system and passed. They rely on increased break and line management abilities to ensure that any sudden weight shift can be managed ideally without causing issues. These useful systems may cost more than the simpler options but allow you to rely on a single system rather than having to find the right one for the job at hand. The ideal way to ensure peace of mind on-site is knowing you can manage the task on a flat surface, steep hill, or vertical drop.

When you need to find the best winch and hoist systems available, be sure to speak to our professional team. We can discuss your needs and requirements and what your task will require. With expert advice, you can invest in the ideal solution for your needs. Contact us today to find out more about these devices.

Pro-Bel’s roof-mounted material hoists

Pro-Bel offers a range of hoisting equipment including, but not limited to, the following:

Material Hoisting Arm – Electrical – 1000lbs Capacity

This all-steel material hoisting arm has an electric motor for ease of operation. It has a maximum reach of 8 feet and 6 inches and a working capacity of 1000 lbs.

The hoist can be adapted to Pro-Bel davit bases and installed in any structure.

Material Hoisting Arm – Manual – 1000lbs Capacity

This all-steel material hoisting arm allows workers to manually lift materials 1000 lbs or under to the upper levels of a building. The maximum reach of this roof-mounted material hoist is 8 feet and 6 inches. This hoist can be adapted to Pro-Bel’s davit bases and installed in any structure.

Material Hoisting Arm – Manual – 350lbs Capacity

This all-aluminum material hoisting arm allows workers to manually lift materials 350 lbs or under to the upper levels of a building. The maximum reach of this roof-mounted material hoist is 8 feet and 6 inches. This hoist can be adapted to Pro-Bel’s davit bases and installed in any structure.

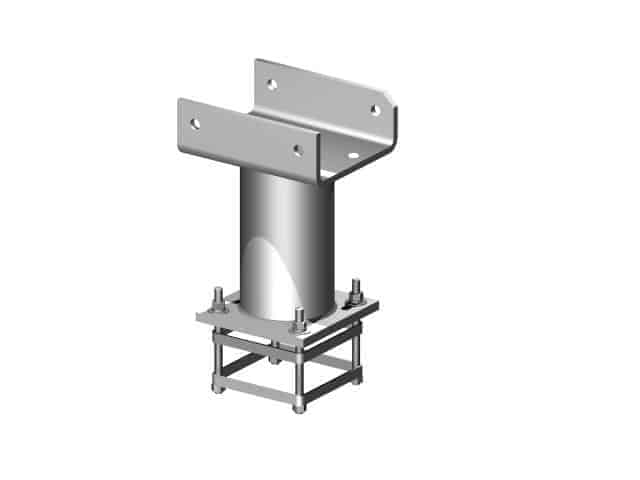

Roof-mounted Material Hoist Bases

Pro-Bel’s standard material hoist bases are, in fact, the same davit bases we use with our window washing equipment. Our hoist arms were manufactured to pair with our countless bases, including, but not limited to:

- Cast in Place base

- Weld to Structure base

- Bolt Through base

- Cast in Cage base

- Wrap Around base

- Material Hoisting Base