Horizontal Lifeline Systems (HLLs) are solutions that protect workers operating near roof edges or elevated areas without compromising mobility. These engineered safety solutions provide continuous fall protection, enabling safe mobility across hazard zones and helping companies comply with OSHA and ANSI standards.

Workers within 1.8m of a vertical drop – a ‘fall hazard zone’ or ‘restricted area’ – are required by law to be tied off to an anchor point (OSHA 1926.502 and ANSI/IWCA 1-14.1). However, single anchor points may not be ideal in cases where mobility is required over an extended horizontal distance. This is because they may leave workers open to the dangers of swing fall hazards. In this case, a fully engineered horizontal cable lifeline system is used instead, incorporating strategically laid-out tieback anchors with an HLL cable running through them.

How Do Horizontal Lifelines Work?

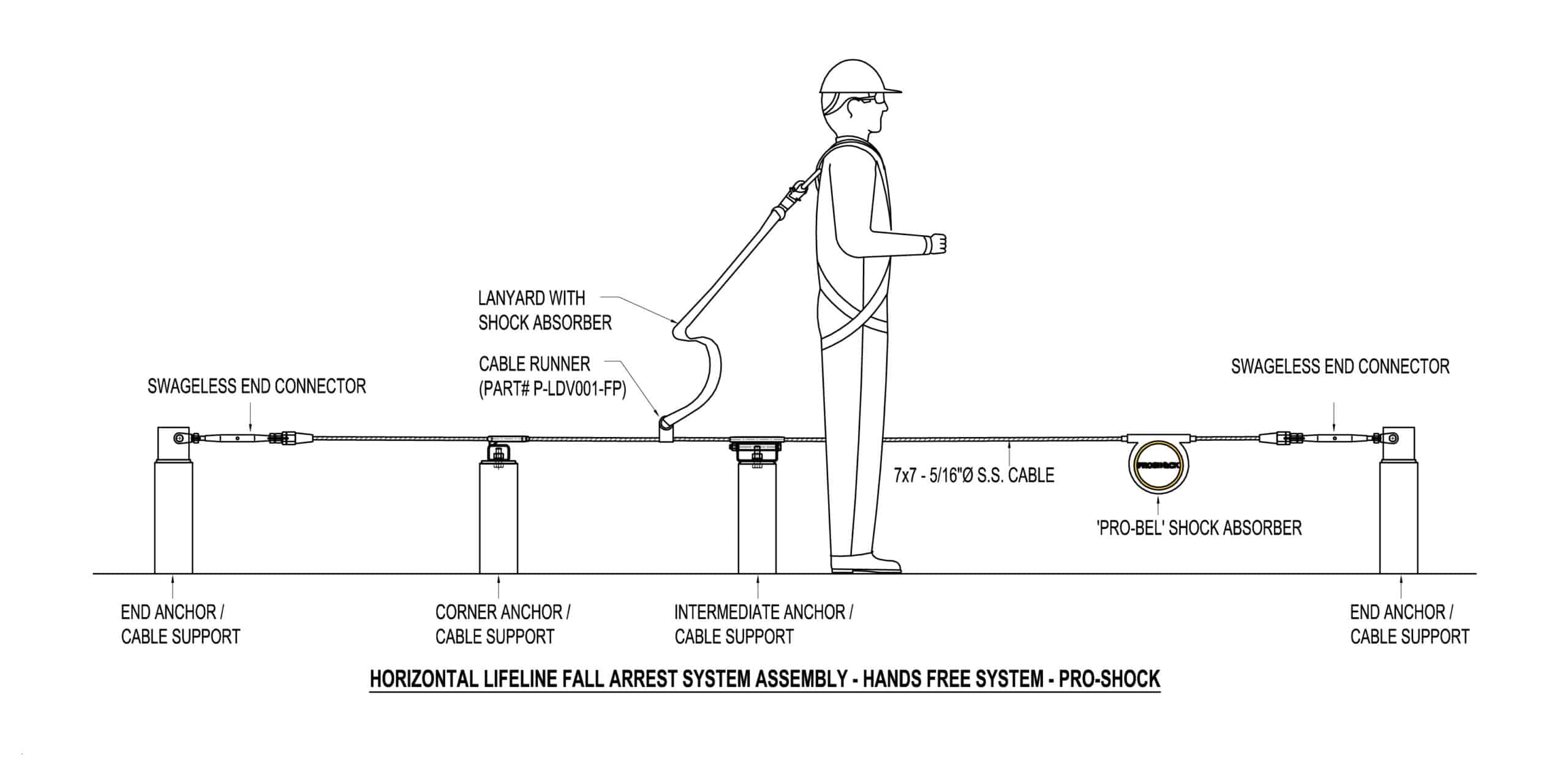

A horizontal lifeline is a permanently installed, multi-span, anchored cable system that serves as a point of attachment for travel restraint or fall arrest lanyards. They can also be referred to as a fall protection lifeline system or a fall restraint system. In the image below, you’ll see that there are several main components to a horizontal cable lifeline system:

- Stainless Steel Cable

- Shock Absorber

- End, Intermediate, and Corner Anchors (also known as cable supports)

- End Connection

- Cable Runner

- Hands-Free Lanyard or Double Lanyard

- Full Body Harness

Hands-Free vs. Double Lanyard Horizontal Lifelines

Pro-Bel offers 2 types of Horizontal Cable Lifeline systems: Hands-Free and Double Lanyard.

The hands-free horizontal lifeline employs a cable runner that mechanically bypasses all intermediate anchors, providing the worker with continuous ‘hands-free’ protection. They are typically installed as a fall protection solution on sloped rooftops.

Double Lanyard horizontal lifelines are our more economical system, but are just as self-explanatory. Instead of mechanically bypassing intermediate supports, the user must manually bypass them using a double lanyard. The double lanyard allows for 100% tie-off at all times and is equipped with an inline shock absorber.

For more information on fall protection lifelines, please read our guide on Types of Horizontal Lifeline Systems

Applications of Horizontal Lifeline Systems

Horizontal Safety Lifeline Systems are designed for safe horizontal mobility in hazard zones (any area within 1.8m of a vertical drop). In practical settings, this is often a narrow roof area or walkway that requires fall protection over an extended distance.

They are combined with other fall arrest systems in confined spaces, clerestory areas, or for safe entry and exit from work zones where façade access or window washing equipment is installed. For example, suppose a high-rise window cleaner needs to access window cleaning equipment in a hazardous zone. In that case, an HLL provides safe passage and movement to set up primary rigging equipment (such as a stage, cage, or bosun’s chair) and lifelines.

In other situations, maintenance may be required near a roof’s edge, where the worker would tie off to a cable system to safely enter the area and tie off to a separate roof fall protection system.

Designing a Horizontal Lifeline System

Permanent horizontal lifeline systems utilize strategically placed tie-back anchors, allowing the HLL cable to run through them. This enables workers to access all rooftop areas without risk of falling over the edge. The anchors are placed at least six feet away from the roof edge, given that that is the length of a worker’s lanyard. If there’s equipment blocking that area, sometimes tie-back anchors need to be placed in the hazard zone, which is why it’s essential that an HLL system can act as a fall arrest system if needed.

There are numerous factors and strategic approaches used to create an optimized design. Watch our video on horizontal lifeline system design (rooftop fall protection) to learn more about this topic.

Careful Engineering is Required

While HLLs are primarily designed to provide horizontal fall restraint, they are also carefully engineered to arrest workers in the event of misuse or overload. Factors such as cable geometry, excessive attachment of personnel to the cable system, or accidental rigging of suspension equipment can cause the working load to exceed the maximum.

Therefore, Pro-Bel HLLs are engineered with a factor of safety of 2, and other important design considerations are made to ensure the complete safety of workers.

Pro-Bel Horizontal Lifeline Equipment

For more technical details, including size charts and equipment specifications, please refer to our Horizontal Lifeline Catalogue.

Share this Post