Why Fall Protection Lifelines

Falls are one of the leading causes of injury or death in the workplace, particularly on rooftops, where there is a greater risk of falling. Proper fall protection systems are critical for any worker operating at heights. Herein we will be explaining two types of fall protection lifelines: horizontal lifelines and vertical lifelines. Understanding the differences between the two types and knowing when to use each is essential for fall prevention and protection in the workplace.

Horizontal Lifeline Systems

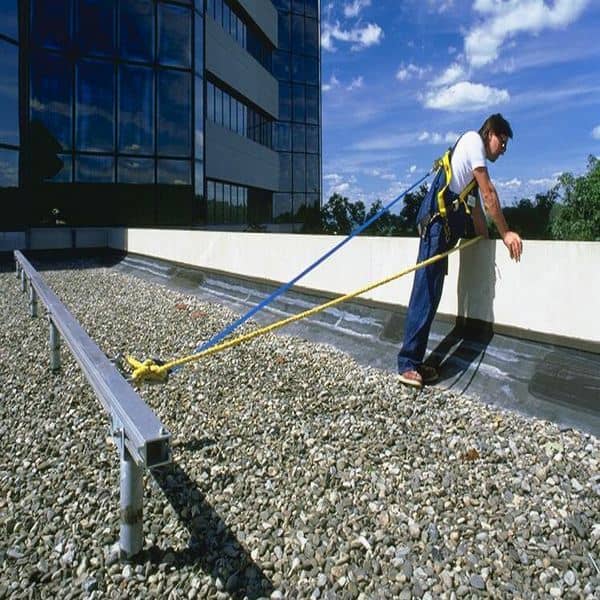

A Horizontal Lifeline System (HLL) is a safety system installed on rooftops as part of an anchorage network, designed to protect workers operating near fall hazards such as roof edges, skylights, or elevated walkways. The two main types of horizontal lifeline systems are Hands-Free and Double lanyard. These systems are used as fall restraints or arrest mechanisms for workers who must approach within 6 feet of a roof edge. The cable is connected to secure anchor points, allowing workers to traverse the area the system covers freely.

Professionally designed rooftop anchorage points will enable the workers attached to the horizontal lifeline to traverse to all equipment within the roof’s hazard zone without approaching the edge.

Suppose anchor points need to be installed within the hazard zone. In that case, the horizontal lifeline system can be used as a fall arrest system, provided there is enough distance to the lower level to adequately arrest the fall without bottoming out or hitting the lower level or an obstruction.

Explore our Horizontal Lifeline (HLL) Systems

Vertical Lifeline Systems

A Vertical Lifeline (VLL) is a fall protection safety system designed for vertical movement, most commonly used during facade maintenance or window washing when workers need to ascend or descend a building. They’re implemented as safety lines when window washers or other facade maintenance personnel descend or ascend a building. The lines are attached to tieback anchors installed behind the window washing equipment at a specific offset angle to minimize and stay within the allowable swing fall hazard (aka pendulum effect).

If the primary safety line snaps or fails, the vertical lines act as a fall arrest system, suspending the fall until help arrives. These fall protection systems are vital for protecting workers in the unlikely event of primary system failure.

For a full overview of all the lifeline types, check out our Types of Fall Protection Lifelines guide

What is the difference?

The primary difference between horizontal and vertical lifeline systems lies in their intended use and application. They both use the same types of equipment (lanyards, permanent roof anchors, and/or wall tieback anchors), but as the name suggests, one is used for vertical application, and one is used for horizontal application. Horizontal lifelines prevent falls by restricting movement within a safe distance from the roof edge, acting as a fall restraint system. On the other hand, vertical lifelines are designed to catch a fall as it occurs, thereby making them a fall arrest system.

Which fall protection lifeline to use

Whether you incorporate vertical or horizontal lifelines on the building’s rooftop depends on the intent. Vertical lifelines are used for facade descent, and horizontal lifelines are used for travel restraint (or sometimes fall arrest) when traversing horizontally on a rooftop.

Download our Horizontal lifeline brochure for more details

If a building requires facade maintenance, such as window washing, a vertical lifeline is needed for the workers ascending or descending the façade. Horizontal lifelines are incorporated for buildings with low rooftop parapets. It’s common for rooftop anchorage systems to be designed for horizontal and vertical lifelines.

Share this Post