Project Overview

Greater Cincinnati’s newest riverfront icon, The Ascent at Roebling Bridge in Covington, is a 22-story luxury condominium tower project comprising 62 units that the Ohio River and the Roebling Suspension Bridge inspired. Its signature arcing profile and curved walls reaching, twisting, stretching, and spiraling upward in motion is an unusual concept in building, posing a considerable challenge regarding window cleaning and exterior building maintenance using suspended equipment. We shouldn’t be surprised at this original work of art since Daniel Libeskind was the architect chosen for the new Freedom Tower in New York City, another unique landmark building with some unusual features.

Pro-Bel Technical Approach

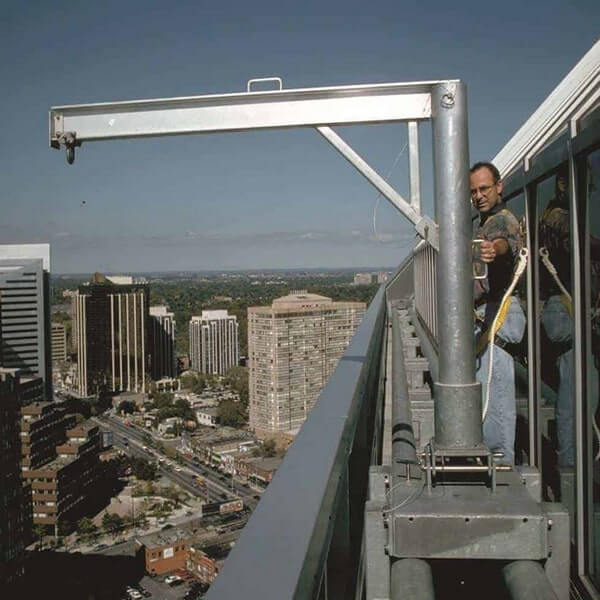

This novel building is one of Pro-Bel’s more exciting challenges. The Pro-Bel engineers’ first tasks were to provide safe horizontal movement over the steeply pitched roof. This was achieved using eight separate fully engineered horizontal cable lifeline systems that provided a secure means of access to and egress from work zones, i.e., once at a work zone, the worker can tie off to a separate fall protection system and access primary rigging equipment. In this instance, suspended maintenance workers will travel to the edges of the roof (that have low or non-existent parapets) and clip onto their respective u-bar lifeline and suspension anchors, spotted around the top of the roof, for travel down the side of the building using a roof rigged bosun’s chair or ground rigged platform. Unusually, almost all of the roof anchors on The Ascent roof were either horizontal (at the roof edges) or sloped (on the field of the roof), a rather special situation.

Challenges in Exterior Maintenance

To make things even more interesting, three faces of the curved building were angled (and slightly curved vertically!) from top to bottom, not unlike the leaning tower of Pisa. To ensure workers could access the inward angle faces of the building, a vertical down-rigged line or “standing line” with a tensioning device anchored at a ground level or pool level was used from top to bottom at appropriate horizontal intervals. After hooking up suspension lines at roof level, the platform is picked up at ground level and hoisted to roof level using the standing- line for stability. As the platform is lowered, workers can access a wall anchor (using a hook) to pull themselves a few feet toward the wall on every second floor. When finished with window cleaning/maintenance, they reverse the procedure to the roof level and then ride back down using the standing line again for stability, which is removed upon completion of maintenance activities. The ground-level standing-line anchors are concealed using metal cover plates when not used.

Specialized Safety Systems at The Ascent

Other types of U-bar safety anchors used in the project included concealed terraces, soffits, and vertical roof anchors. It is one of Pro’Bel’s more interesting window cleaning/exterior building maintenance projects.