Fall Arrest VS Fall Restraint VS Fall Prevention

Many people debate over the true definition of fall protection. However, for working at heights, fall protection is generally defined as encompassing different forms of fall prevention systems, such as fall arrest and fall restraint.

Fall Arrest System

A fall arrest system prevents a person from reaching the ground in the event of a fall. An example of fall arrest is a worker tripping over the edge of a building but then being suspended midair by a lanyard tied to a cable system, preventing them from reaching the ground.

Fall arrest is considered the stop of a fall if one is to occur. All codes state that the human body cannot experience more than 4 kN of force. The fall must be stopped (or arrested) within 1.5m to avoid this happening. To prevent this fall properly, there must be at least 6m of vertical distance to stop this free fall. This height allows for the lanyard length, D-ring, and rope length to be appropriately accommodated.

Fall Restraint System

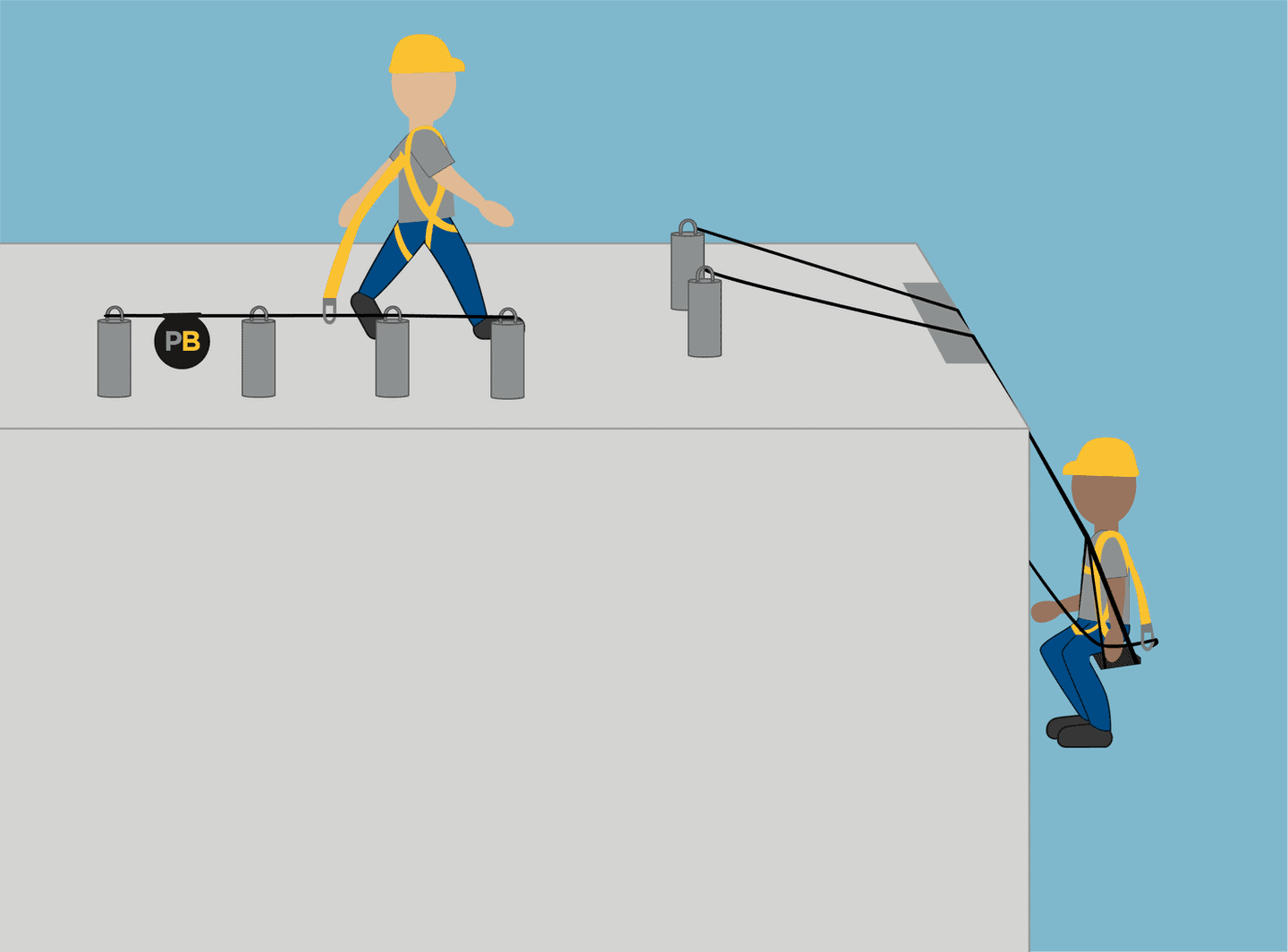

A fall restraint system prevents a worker from reaching a fall hazard by attaching a lanyard to their harness. The horizontal lifeline is measured out so it can go no further than the roof edge.

Fall restraint is the first approach we design for. This begins with keeping a worker outside a fall hazard area. The fall hazard zone encompasses any area within 2 meters of the unprotected roof edge of the building. Equipment will be placed outside of this zone to stop the fall from occurring. This typically can be completed with stand alone anchors or a Horizontal Life Line system (HLL) as shown in the header image and illustration. This keeps the worker safely tied off should they need to be within the fall hazard area.

Fall Prevention

Data shows that falls are the most common accident in the construction industry, with 75% occurring at elevations of less than 3 stories. Preventing falls is crucial to maintaining a safe workplace. To prevent the occurrence of a fall, systems such as guardrails would be implemented to block off the edge for anyone on the roof.

A comprehensive fall protection system can include:

Cable Systems:

These are ideal when workers need to move horizontally and provide a continuous path for fall protection.

Fixed Ladders:

This offers safe vertical access to elevated work areas, and it is equipped with fall arrest systems.

Guard Rails:

This is a critical component of fall restraint systems, and these barriers protect workers from hazardous falls.

Permanent Roof Anchors:

These personal fall arrest systems are essential for areas with limited fall protection infrastructure. They provide secure attachment points and are key components of a comprehensive fall protection system.

Designing a Fall Protection System

When designing a fall protection system, consider the following factors:

Function

What type of work will be completed while the system is in use? Some examples include:

-Fixing, replacing or servicing

- Antennas

- Cooling towers

- Drains

- Equipment located on the facade

- Lights

- Mechanical Units

- Pipes

- Roofing

- Satellites

- Surveillance cameras

Frequency

How often will this work occur?

- For expected, routine, and scheduled maintenance, implement the most user-friendly system to encourage its use.

- For unexpected, non-routine, and unscheduled maintenance, implement the most basic and cost-effective system.

Users

Who Uses Fall Protection Systems

- A worker who is trained and supervised may not require as much equipment as someone unfamiliar with fall protection and fall arrest systems.

Read our guide on the top 6 considerations for designing a fall protection system

Regulatory Requirements:

Regulations for fall protection requirements vary by region; however, in most states, any parapet less than 42 inches high requires a fall protection system. In Canada, if the parapet is less than 36 inches in most regions, a fall protection system is required. Canada additionally requires systems based on the height of the building. For more detailed information, please refer to Canadian Building Codes and Regulations on our Canadian website.

Share this Post