Horizontal Lifeline Systems

Rooftop Horizontal Lifeline Systems For Fall Arrest

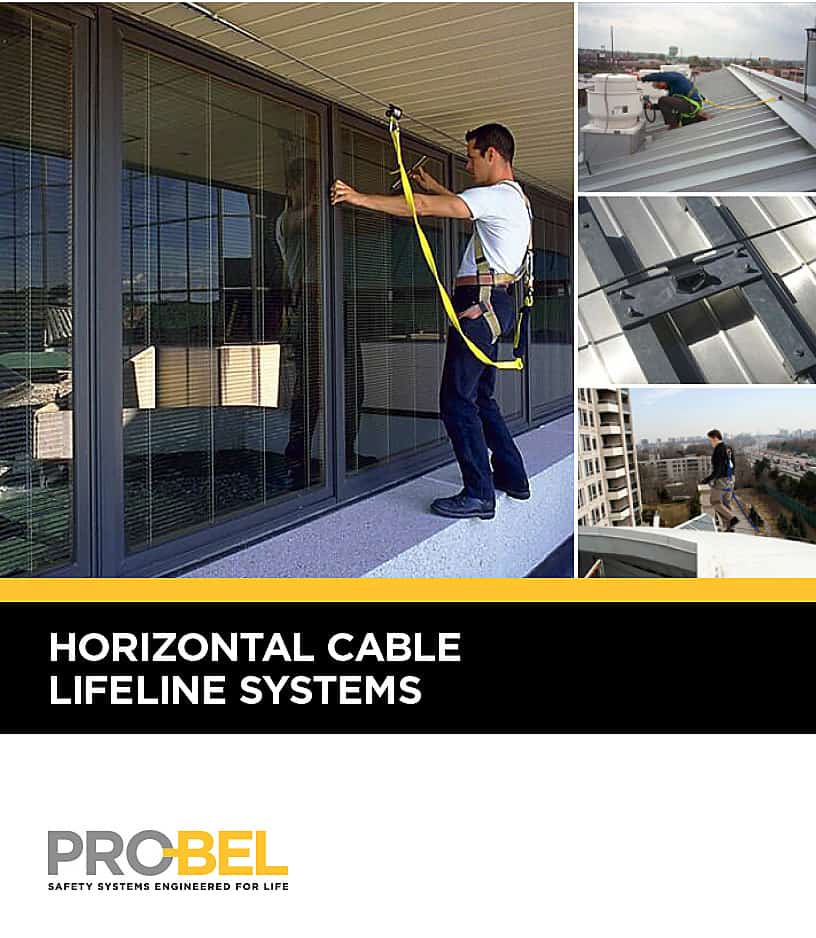

A horizontal lifeline system (HLL) is a versatile solution that serves as both a fall restraint system and a fall arrest system. It consists of two permanent roof anchors and a horizontal lifeline to protect rooftop workers from falling over the edge while allowing safe mobility. These systems are crucial in rooftop fall protection, ensuring that workers are either restrained from reaching fall hazards or arrested in the event of a fall.

For workers who require safe horizontal mobility over long distances within the proximity of a vertical drop, single-point anchors may prove neither viable nor appropriate. As a practical solution to this common problem, Pro-Bel recommends the use of a horizontal cable lifeline system. This permanently installed, multi-span anchored cable is an attachment point for travel restraint or fall arrest. Due to the often-particular nature of structures that demand this type of system, horizontal lifelines fall under the category of highly restricted fall protection and require extremely careful engineering - the very kind of engineering for which Pro-Bel is known.

Regular maintenance and inspection are crucial for both fall restraint systems and fall arrest systems. In corrosive environments, it is recommended that lifeline systems be inspected more frequently than annually. Signs of wear, damage, or corrosion can compromise the system's effectiveness, leading to serious safety hazards. Certified professionals should conduct inspections to ensure that anchor points, wire ropes, and other components meet OSHA and ANSI standards.

When Horizontal Lifelines are used for Fall Protection

A horizontal lifeline is used for horizontal, sloped, or vertical mobility over extended distances while working close to a vertical drop, e.g., within 6'-0" (1.8 m) of the roof edge, skylight, or any high, narrow, level roof area or walkway not protected by a 42" (1.067m) high guardrail. As its name suggests, a Horizontal Lifeline (HLL) system connects between two anchor points to offer continuous, safe mobility along a fall hazard.

These systems act as both fall restraint and fall arrest solutions, serving as an alternative to single anchor points when independent anchors do not provide the required safety.

Generally, a horizontal fall protection lifeline provides safe horizontal movement to a workstation and back. In high-rise building operations, horizontal lifelines allow window cleaners to move safely along the roof, providing fall protection while accessing equipment (stage, cage, or bosun's chair) and lifelines. In this instance, the window cleaner must be able to disconnect the "lanyard cable runner" anywhere along the cable, i.e., at any given workstation, and take it down to the ground while cleaning and back up to the roof again for reconnection to the HLL cable, for safe passage to the next workstation or entry/exit position.

Types of horizontal lifeline systems

1." Hands-Free" Horizontal Lifeline:

A stainless steel 5/16" (8 mm) cable lifeline system employs a runner that follows the worker along the cable and mechanically bypasses all intermediate brackets without disconnecting. Thus, the system provides continuous "hands-free" fall protection and ensures safe, uninterrupted movement regardless of travel surface geometry.

Examples of hands-free horizontal lifeline equipment:

2. Double Lanyard (DL) Horizontal Lifeline:

A galvanized or stainless steel 5/16" (8 mm) cable system employing a double lanyard method to provide 100% tie-off and an inline shock absorber to reduce the applied loads to the end and corner anchors. The DL system is more economical than the "Hands-Free" system; however, there is a risk of human error if workers are completely detached during the transfer procedure required on either side of anchor points, i.e., non-continuous.

Examples of Double lanyard equipment: