A Safer Alternative to Makeshift Anchor Points

Before the roof anchor became the standard in the industry, workers would tie themselves off to whatever they could. If the makeshift anchor point wasn’t sturdy, this would pose a great risk of death or injury if a fall were to occur. Pro-Bel patented the first roof anchor in North America and changed the game for worker’s safety.

Nowadays, the industry has standardized tieback anchors available for rooftop workers, offered as either a single point anchor or a horizontal lifeline system (also known as a horizontal fall protection system). They’re typically installed on buildings that have a parapet under 42 inches and equipment within proximity to the roof edge.

How rooftop workers use roof anchor points

When the hazard zone (within 10ft of the roof edge) has no parapet and equipment that needs to be maintained, workers use roof anchor points to secure themselves to the building. Workers use roof anchor points as fall protection in the form of either a horizontal lifeline system or a single point anchor.

Horizontal Fall Protection System

When implementing a horizontal lifeline system, the permanent roof anchors are laid out so a cable can go through them and allow reach towards any equipment in the hazard zone. Then, the worker attaches their lanyard to the cable so they can traverse the hazard with reassurance that the horizontal lifeline system will catch them in the event of a fall.

Single Point Anchor

A single point anchor has the same purpose of a horizontal fall protection system, but the roof anchor point stands alone and the worker ties themselves off with a simple know rather than setting up a whole cable line.

Anyone using these systems is required to have their up-to-date working from heights so there’s no risk of injury or death due to unfamiliarity with the equipment.

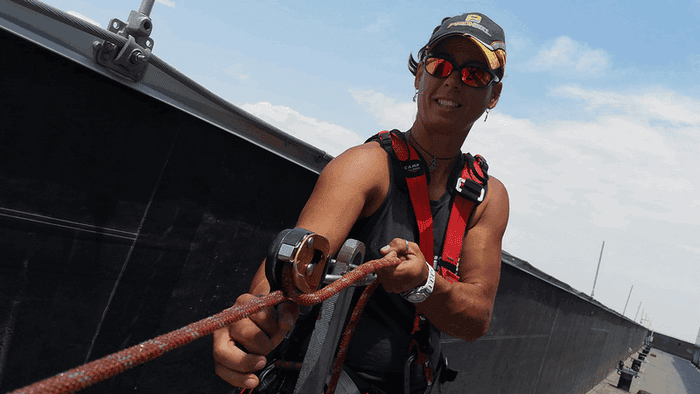

How suspended maintenance workers use roof anchor points

Suspended maintenance workers use roof anchor points to either act as a tieback anchor for their lifeline or to host both their primary suspension line and lifeline.

Although window washers and other suspended maintenance personnel are associated with davits and platforms, most direct descent work involves permanent roof anchors and Bosun’s chairs. This type of setup is used on buildings under 300ft (or 90m in Canada).

For some buildings, they use descent equipment such as davits or outrigger beams to host their suspension lines and use fall arrest anchors for their safety lines. Workers who routinely work on buildings with a drop distance of 300 ft would use this type of set up.

Share this Post