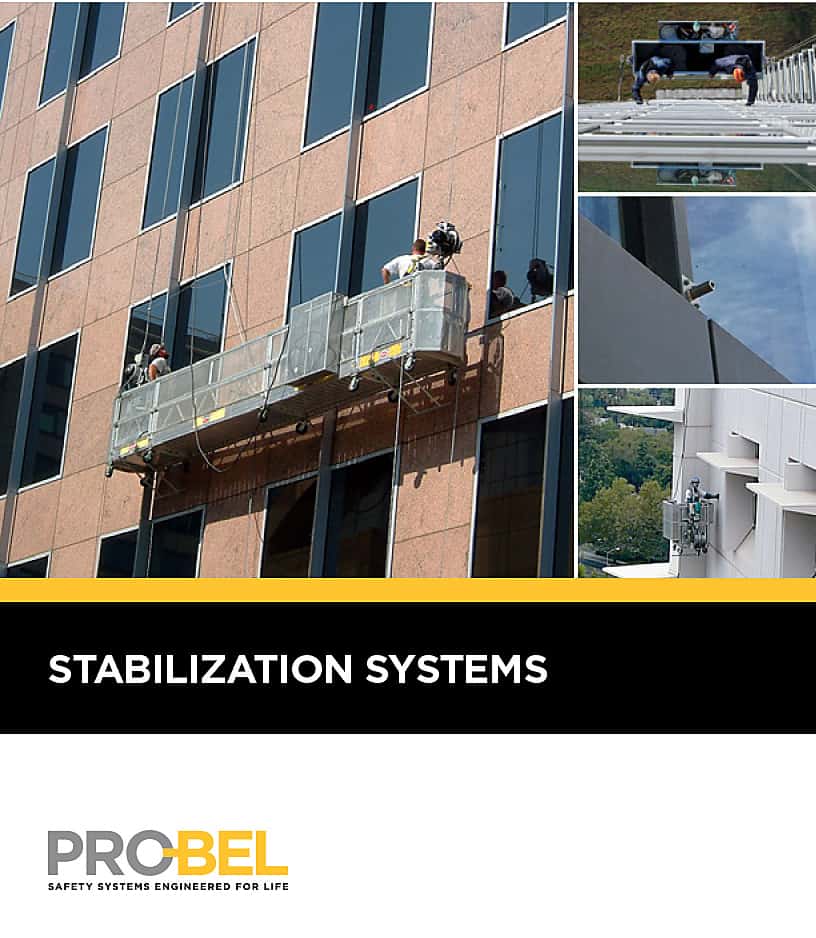

Stabilization Systems

Pro-Bel stabilization systems are designed to keep suspension equipment (including platforms, cages, and bosun chairs) in contact with a building's facade, thereby preventing undesired movement. Without stabilization, worker safety could be in jeopardy due to wind action, or building faces could become damaged due to equipment impacting upon them. Additionally, stabilization systems help to protect building faces from damage caused by the potential impact of suspension equipment. Stabilization systems are mandatory in the case of permanently powered platforms that are purchased specifically for a given building.

When are stabilization systems implemented?

Permanent powered platforms purchased specifically for a particular building require a stabilization system. Permanent powered platforms are mandatory in New York State on all buildings 75'-0" (23 m) and higher and in California on all buildings 130'-0" (39.6 m) and higher.

Currently, federal OSHA covers the subject of stabilization under 1910.66, Subpart F - Powered Platforms. Subpart F is confined to powered platform installations "permanently dedicated" to a specific building. Transportable platforms used to service buildings on an occasional basis are covered by 1910.28, Subpart D, Walking-Working Surfaces. Subpart D requires the contractor to securely lash temporary platforms to the building.

Types of stabilization equipment for Permanent Powered Platforms:

Continuous Stabilization:

When using a powered platform, it is recommended that mullion tracks be employed for rigging flexibility (i.e. can be roof or ground-rigged). Tracks must be coped out or designed so that platform trolleys or sliding shoes can be inserted at both the top and bottom of the building.

Intermittent Stabilization:

Where intermittent stabilization is employed, it is recommended that buttons or detent pins be installed in vertical rows starting at the highest convenient elevation. The maximum vertical interval between anchors shall be three floors, directly below and in line with primary rigging equipment positions, i.e. davits or outriggers.

Types of stabilization equipment for non-permanent platforms:

It is recommended that a building face stabilization system be considered on all buildings over 130'-0" (39.6 m) consisting of mullion tracks or buttons/detent pins to protect the face of the building in accordance with OSHA minimum requirement of lashing the suspended platform cable to the face of the building.

For buildings over 300'-0" (91.4 m) in height, it is imperative the building be equipped with one of the following stabilization systems:

Provision for davit bases anticipating future roof-rigged davit arms and stage transfer locations. Installed buttons on every third floor starting at the highest elevation in line with suspension cables.

Buttons or detent pins at every floor in line with suspension cables.

Installation of mullion guides (tracks) on the complete building if feasible.

As a minimum, installation of one platform "drop" using mullion guides (tracks) with buttons on the balance of the building at every third floor from roof to ground level in line with suspension cables (roof rigged davit system is required)